Mitutoyo CMM Co-Ordinate Measuring Machine

Our CRYSTA-Apex S is a high-accuracy CNC coordinate measuring machine that guarantees. a maximum permissible length measurement error of E0,MPE=(1.7+3L/1000) μm.

It is running PC-DMIS CMM PRO which is the world's leading Coordinate Measurement Machine (CMM) software. Its powerful capabilities are used to measure everything from simple prismatic parts to the most complex aerospace and automotive components.

- 1200x1200x1000 Measurement window

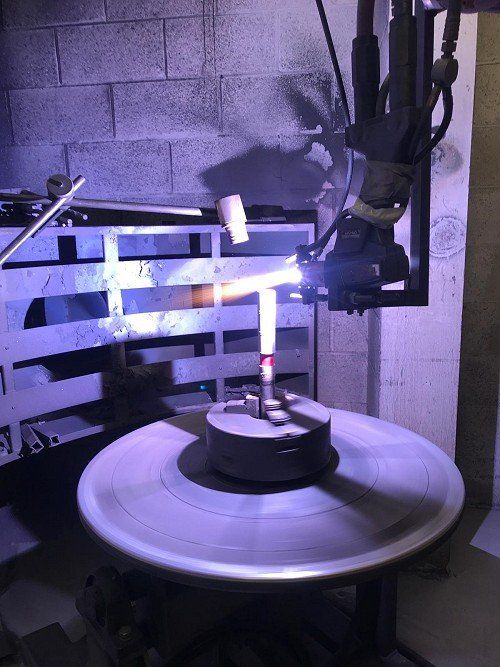

Thermal Spray: Plasma Spray

For those who are unfamiliar with plasma spray, the process involves injecting a powder into a high temperature plasma flame where it is heated and accelerated onto the surface of a component. The process provides high particle velocities leading to relatively dense, low porosity coatings.

A variety of materials including metals, ceramics, cermets and plastics can be applied with the benefit of restricting bulk component temperatures below 150°C in most cases.

Although extensively used in the Aerospace sector, the process is also widely used in the Oil, Gas, Biomedical, Textile, Printing, Automotive and Construction industries.

The process provides component surface enhancement for wear resistance in fretting, abrasive and sliding applications, corrosion resistance, thermal insulation or a combination of these, both under ambient and high temperature conditions.

Thermal Spray: Combustion Powder

Similar to plasma spraying the process involves injecting a powder into a heat source, in this case an oxygen/acetylene flame. Particle velocities are lower leading to increased porosity, making it an excellent choice for relatively low cost abradable /clearance control applications.

Thermal Spray: Wire Spray

Similar to combustion powder spray, a material feed stock, in this case wire, is fed into an oxygen/acetylene flame. Compressed air surrounds the flame and propels the molten tip onto the prepared surface.

Typically used to provide low cost wear resistant coatings and also for dimensional restoration. Materials include pure metals e.g. copper (conductivity), molybdenum (lubricity), zinc (corrosion resistance) as well as alloys such as stainless steel, bronze, NiAl for wear and corrosion resistance.

Paint Spray

Our paint processes are based around conventional HVLP spray methods.

Materials include dry film lubricants, polyurethanes and enamels. This is further enhanced by the ability to apply water-based aluminium and sacrificial corrosion-resistant coatings.

Organic Based:

- Enamel

- Dry Film Lubricant MoS2, graphite filled

- Two Pack Polyurethane

- Hot Hard Anti-Adherent

- Polyimide

- Intumescent

- Epoxy

Water Based:

- Sacrificial Aluminium Coating designed for use in challenging environments such as aero engines, power generation and marine environments. Spray applied material is used on turbine blades, rotors, shafts and landing gear to protect components from salt laden atmospheres, high temperature oxidation, chemicals and abrasives.

- High temperature marking paints

Grinding

After a 12 year partnership between Grindrite (North East) and MPS Ltd , Grindrite was acquired and integrated into MPS in May 2019

We specialis in cylindrical, surface, rotary and large ring grinding in the Aerospace, defence and space sectors, as well as supporting other industries within gas and oil and automotive. MPS holds accreditation to AS9100 and ISO9001 as well as being an approved supplier for Rolls Royce Plc.

Turn Key Processing

Working through partners enables us to enhance the services we can offer including non-destructive testing, Machining and Anodising. Working with these partners gives MPS the ability to offer a fully managed service package, improving lead times, quality control and cost.

- NDT

- Machining

- Anodising

CAPACITY: PLASMA

- 1x Multi-Coat booth Plasma capabilities with Robot manipulator

- 1x 9mce system Plasma capabilities with Robot manipulator

- 1x 9mce system Plasma capabilities with Traverse manipulator

- 1x oxygen/acetylene system which includes combustion and wire spray capabilities

- 2x Blast cabinets

- MPS internal Lab for coating assessment

CAPACITY: PAINT

- 1x organic spray booth

- 1x water based spray booth including humidifier

- 2x large furnace including temperature’s up to 560 degrees

- 2x small furnace including temperature’s up to 350 degrees

- 1x drying room

- 3x blast cabinets

- 1x burnish cabinet